2. Installation

of the 2nd , 3rd spindle at Z axis

3. Extending of the clearance’s height at

Z axis to 310mm.

4. Automatic tool change system

5. 3D Laser scanner with accuracy 0.001mm

of scanning

Necessity

of a computer model creation of an object for it’s

further manufacturing by the CNC router machine.

But there are some difficulties to make a high quality

of 3D model. Necessity

of a computer model creation of an object for it’s

further manufacturing by the CNC router machine.

But there are some difficulties to make a high quality

of 3D model.

• its takes a very long time to make 3D model

• qualified designer

• high cost of 3D model execution by outside party.

In many cases it is possible to solve the abovementioned

problems by using a 3D scanner. Installation of

this device for the CNC router machine allows to

produce a fast and exact scanning of almost any

object.

For example, it is possible to execute a plasticine

model and to scan that. Then we get a completed

computer model.

Also it is possible to scan a completed 3D product

(for example any figurine or carving on wood, etc).

Then after some correction by 3D editor program

on Your PC, you can produce this model at CNC router

machine of any material you wish.

Advantages of this technology are:

- there are no need of designer participation in

order to prepare a 3D model

- Simple preparation

- Manual modeling of one big carved element could

take a few weeks. But scanning and some correcting

will take just a few hours!

- High precision that can not be made manually (by

manual modeling)

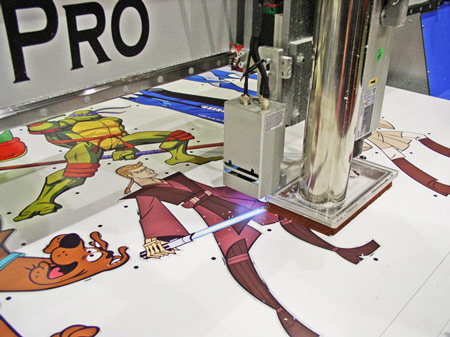

How does it work:

The CNC machine with laser scanner is three-co-ordinate

system which smoothly moves a laser head over scanned

object. During this moving using laser ray a distance

is constantly measuring in a current point between

a laser head and an object. The measuring head moves

over all surface of an object, and coordinates of

all measuring points on a surface are registering

into a file which then can be opened by any modern

3D editor and in case of necessity to make a correction

of received model.

As laser scanning is a contactless measuring method,

it allows scanning with high speed and high accuracy

(up to thousand points per second). Very important

fact is that is impossible to scan transparent and

mirror object.

How does laser head works:

The laser ray goes on measuring object and as being

reflected it goes back into the head.

Result of 3D scanner’s work is a computer model

at STL-file format. STL (stereo lithography) format

is the most prevailing format for transferring 3D

models, therefore STL files can be opened and edited

at any modern 3D editor programs :3DS Max, Maya,

Rhino, ArtCAM, Type3 etc.

And also model at STL format is possible to use

at modern CAM-system: SolidCAM, AlphaCAM, MasterCAM,

SurfCAM etc.

Using of 3d scanner allows to accelerate and to

reduce a price of creation of 3D models. Besides,

in many cases it is the only unique way to create

a lot of models at rational time and for rational

price.

6. Inexpensive contact 3D scanner

7. Tool length sensor – “clever nose”

8. Laser measuring of material’s thickness.

9. A portable manual control panel

10. Vacuum pressure system with 2, 4, 6,

8 zones (4kWt or 8kWt)

11. Shaving removal system

12. Auto oiling and cooling system

– directly on the tool and cutting zone. Especially

it is necessary for processing of metals.

|

Necessity

of a computer model creation of an object for it’s

further manufacturing by the CNC router machine.

But there are some difficulties to make a high quality

of 3D model.

Necessity

of a computer model creation of an object for it’s

further manufacturing by the CNC router machine.

But there are some difficulties to make a high quality

of 3D model.